Essential Tools and Protective Gear for Safe Repair Work

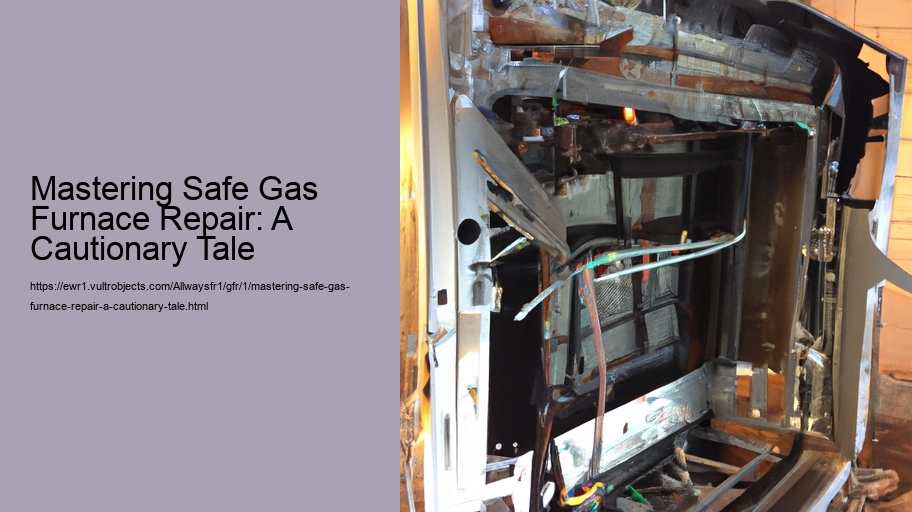

Mastering Safe Gas Furnace Repair: A Cautionary Tale

When it comes to repairing a gas furnace, safety is not just a priority; it's an absolute necessity. Call All-Ways Heating & A/C for gas furnace repair services in the Snohomish County area. Every year, countless individuals, both professional technicians and intrepid homeowners, find themselves facing the hazards that come with handling such combustible systems. The difference between a repair story with a happy ending and a cautionary tale often lies in the use of essential tools and protective gear.

Firstly, one must recognize the inherent dangers when working on any gas appliance – the risk of fire or explosion from gas leaks, potential carbon monoxide poisoning, electrical hazards, and even physical injury from improper handling of components. With these risks in mind, assembling an appropriate toolkit and donning protective gear become non-negotiable steps before beginning any repair work.

A reliable multimeter is at the heart of diagnosing furnace problems accurately. It ensures that you can safely check for live currents and continuity without risking an electric shock. Another essential tool is a gas leak detector or electronic sniffers which are specialized in detecting flammable gases like natural gas or propane. This device can be life-saving by alerting you to unseen leaks that could lead to catastrophic consequences if ignited.

Hand tools like screwdrivers, wrenches, pliers, and nut drivers are staples in any repair job. However, they should be insulated to protect against electric shock when working near energized circuits. A flashlight or headlamp is also crucial since much of the work may take place in dimly lit areas where built-in furnace lights are inadequate.

Protective gear includes safety glasses to shield your eyes from flying debris or sparks during repairs and thick gloves that provide protection against sharp edges while still allowing for dexterity. In certain situations where heavy lifting might be involved, steel-toed boots can prevent foot injuries.

Respiratory protection such as masks should not be overlooked either — especially when dealing with potential mold spores or insulation fibers that could be stirred up within ductwork. When working under conditions where carbon monoxide presence is possible due to malfunctioning equipment or incomplete combustion processes within the furnace system itself — having a personal CO detector on hand adds an extra layer of vital protection.

Beyond having the right tools and gear at your disposal lies another important aspect: knowledge and training. Understanding how your particular model of gas furnace operates allows you to identify issues accurately and know when it's safe to proceed with repairs versus recognizing when it's time to call in professionals.

In conclusion, mastering safe gas furnace repair requires more than just mechanical skill — it demands respect for the dangers involved and proper preparation through essential tools and protective gear. A comprehensive approach combining knowledge with safety practices ensures not only successful repairs but also safeguards those undertaking them against becoming characters in their own cautionary tales.

Common Gas Furnace Issues and Diagnostic Tips

Mastering Safe Gas Furnace Repair: A Cautionary Tale

Gas furnaces are workhorses during the chill of winter, providing warmth and comfort to households across the globe. However, even the most reliable gas furnace can run into issues. Mastering safe gas furnace repair is a journey that intertwines technical expertise with an overarching narrative of caution and preparedness. This essay delves into common gas furnace problems and offers diagnostic tips that weave together a cautionary tale for those venturing into the realm of furnace repair.

One prevalent issue faced by many homeowners is the lack of heat emanating from their gas furnace. This problem could stem from a variety of sources such as thermostat malfunctions, pilot light or ignition control issues, or a faulty gas valve. To diagnose this, one should first check if the thermostat is set correctly and functioning properly—sometimes it's as simple as replacing batteries or recalibrating the temperature settings.

Another chapter in our cautionary tale deals with unusual noises emanating from the furnace—an unnerving symphony of bangs, rattles, or whines. These sounds may indicate mechanical problems like loose belts, malfunctioning burners, or problems with the blower motor. Listening closely to your furnace's cries for help can direct you towards tightening screws, lubricating moving parts, or cleaning components that have become dirty over time.

The plot thickens when we encounter a non-functional blower motor; our homes remain cold despite the furnace burning away. Here we must tread carefully; it might be an issue with limit switches which serve as guardians preventing overheating—a safety feature not to be bypassed lightly. heating system replacement Diagnostics involve testing electrical connections and ensuring switches activate appropriately in response to temperature changes inside the unit.

Our cautionary tale takes us deeper into more ominous territory with carbon monoxide (CO) leaks—the silent but deadly antagonist in any gas appliance story. Any repair adventure must prioritize detecting signs of CO leakage through regular inspection of heat exchangers for cracks and ensuring flue pipes aren't obstructed—all while armed with CO detectors placed strategically throughout living spaces.

A less life-threatening but equally frustrating issue is short-cycling where furnaces turn on and off more frequently than they should—a potential harbinger suggesting overheated components or dirty filters hampering airflow.

Mastering Safe Gas Furnace Repair: A Cautionary Tale - heating system replacement

- heat exchanger inspection

- programmable thermostat installation

Efficiency loss is yet another villain lurking within ailing furnaces; high energy bills might signal its presence long before physical symptoms manifest within equipment itself. Diagnosing this foe involves examining heat exchanger blockages or ductwork leaks—areas where precious warmth might escape unnoticed until utility costs reveal their stealthy infiltration.

In mastering safe gas furnace repair, each step taken must be guided by respect for this intricate machine’s complexity paired with awareness of inherent dangers posed by combustible elements under its control. Every diagnosis should begin with power shut-off procedures followed by systematic checks according to manufacturers’ guidelines while wearing appropriate safety gear including gloves and eye protection.

Lastly—and crucially—our cautionary tale underscores that certain repairs should never fall into unqualified hands no matter how brave-hearted one feels amidst winter’s chill grip. When diagnostics lead you towards complex electrical work or adjustments involving natural gas lines—the threshold between DIY enthusiasm and professional intervention has been reached.

Embarking on safe gas furnace repair demands not only skill but also humility in recognizing limits beyond which experts must be summoned lest our well-intentioned hero becomes ensn

Step-by-Step Guide on Safe Gas Furnace Repairs

Mastering Safe Gas Furnace Repair: A Cautionary Tale

In the depths of winter, a gas furnace is not just a convenience but a necessity. Ensuring that it runs efficiently and safely is paramount for any homeowner. However, when things go wrong, the task of repairing a gas furnace can be daunting and fraught with danger if not approached with respect and caution. This short essay serves as a cautionary tale to those who might attempt to repair their gas furnaces without proper knowledge or respect for the risks involved.

Firstly, it's crucial to understand that working on a gas appliance involves risks such as gas leaks, carbon monoxide exposure, fires, and even explosions. That's why most repairs should only be conducted by certified professionals who have been trained to handle hazardous materials and are familiar with local codes and regulations.

Despite this warning, if one decides to undertake basic maintenance or simple repairs after thorough research and preparation, here are some step-by-step guidelines:

1. Prioritize Safety: Before you begin any repair work on your gas furnace, shut off both the electrical power supply and the gas supply to the unit. This will help prevent any accidental ignition or electrocution while working on the system.

2. Consult the Manual: Each furnace has its own set of intricacies; therefore, referring to the owner’s manual is essential for understanding specific instructions related to your model.

3. Perform Visual Inspections: Look for obvious signs of wear or damage such as frayed wires, rusted components or loose connections which could indicate potential problems with your furnace.

4. Regular Maintenance Checks: Replace filters regularly and keep air vents clean to ensure proper airflow throughout your home. airflow testing These steps can improve efficiency and may prevent further issues from developing within your furnace system.

5. Recognize Your Limits: Understand that certain repairs should never be attempted by an unqualified individual - this includes anything related to the heat exchanger, burners, pilot light adjustments or control valves among others.

6. Seek Professional Help When Necessary: If you're unsure about any aspect of repair work or encounter something beyond basic troubleshooting – call in a professional technician immediately.

The tale we must remember is that overconfidence can lead to dire consequences when dealing with complex systems like a gas furnace. In an effort to save time or money, one might skip critical safety steps or misdiagnose problems leading to greater expense down the line due not only monetary cost but also personal health and well-being.

Ultimately mastering safe gas furnace repair does not mean becoming an expert overnight; it means knowing when it’s appropriate (and safe) for DIY measures versus recognizing when professional expertise is required for both safety and peace of mind.

The Importance of Regular Maintenance to Prevent Future Problems

Mastering the art of safe gas furnace repair is not just about fixing immediate issues but also about understanding and appreciating the importance of regular maintenance to prevent future problems. This concept is akin to the old adage, "An ounce of prevention is worth a pound of cure." In the realm of gas furnaces, this couldn't be truer.

Regular maintenance serves as a proactive measure that can save homeowners from costly repairs down the line. It involves routine checks and minor adjustments that keep a furnace running efficiently and safely. The lack of it, however, can lead to a cautionary tale fraught with dangers and unexpected expenses.

Consider a scenario where a homeowner neglects their gas furnace, failing to schedule annual inspections or cleanings. Over time, dust and debris accumulate within the system causing it not only to work harder but also increasing wear and tear on its components. One day, in the dead of winter, the furnace breaks down. Upon inspection by a professional technician, it's found that what could have been prevented through simple cleaning has now caused significant damage that requires expensive repairs or even replacement.

Moreover, safety is paramount when dealing with gas furnaces because they involve combustible fuel. A poorly maintained system might develop dangerous conditions like gas leaks or carbon monoxide buildup which are serious health hazards for residents in any home.

To master safe gas furnace repair means recognizing these risks early on and taking steps to mitigate them before they escalate into emergencies. It includes educating oneself on how different parts work together in harmony - from thermostats to heat exchangers – so that during regular maintenance checks one can spot anomalies quickly.

In conclusion, mastering safe gas furnace repair isn't just about having skills for fixing what’s broken; it's equally about preventing things from breaking in the first place. Regular maintenance plays an essential role in this by ensuring systems run smoothly while simultaneously safeguarding against potential disasters both financial and health-related. Like many aspects of life, care and attention given today can often circumvent calamities tomorrow – creating peace of mind for all involved.

When to Call a Professional: Recognizing Your Limits

Mastering Safe Gas Furnace Repair: A Cautionary Tale - When to Call a Professional: Recognizing Your Limits

In the journey of becoming a proficient do-it-yourselfer, there lies an invisible line between what one can manage and when it is time to call in a professional. Particularly when dealing with gas furnace repair, this demarcation becomes critically important. The story that follows serves as a cautionary tale for those tempted to overestimate their abilities in the face of potential danger.

There was once a homeowner named Alex, who prided himself on being able to fix almost anything around the house. From plumbing issues to electrical work, he had done it all with confidence and success. Then came the day his trusty gas furnace began to falter just as winter's chill set in. Armed with online tutorials and an assortment of tools, Alex set out to tackle the repairs himself.

He started by checking the thermostat and replacing the air filter – simple tasks that he completed without any trouble. However, when it came time to deal with the internal components of the furnace such as burners, heat exchangers, and gas valves, things became less straightforward.

As he proceeded, Alex noticed his limited understanding of these critical parts was proving insufficient against the complexity before him. He tinkered for hours trying various fixes he had learned about online but found no success. Frustration mounted as each attempt seemed only to further complicate matters.

It wasn't until he caught a faint whiff of gas that reality struck him like a cold draft through an unsealed window; his lack of expertise could lead not only to further damage of his heating system but also pose serious risks such as gas leaks or even carbon monoxide poisoning.

Recognizing his limits at last, Alex wisely decided it was time to seek professional help. He contacted a certified HVAC technician who arrived promptly and identified that during his attempts at repair, Alex had inadvertently caused issues with the gas supply line.

The professional quickly addressed all problems safely and efficiently while explaining each step taken so that Alex could better understand where his DIY efforts should end and where expert intervention is paramount. The repair costs were higher than anticipated due both to initial complications from Alex's endeavors and emergency service rates – yet they paled in comparison to what might have been lost if disaster had struck.

This cautionary tale reminds us that recognizing our limits is not an admission of defeat but rather an acknowledgment of prudence particularly in areas involving specialized knowledge and inherent dangers like those entailed in gas furnace repair. While basic maintenance may be within reach for many homeowners learning new skills can be deeply rewarding calling upon experts ensures safety remains paramount above all else.

Real-Life Cautionary Tales in DIY Gas Furnace Repair

Mastering Safe Gas Furnace Repair: A Cautionary Tale

When the chill of winter sets in, a well-functioning gas furnace becomes the unsung hero of a cozy home. However, when things go awry with this complex piece of machinery, the allure of do-it-yourself (DIY) repair can be both tempting and perilous. The annals of DIY repairs are replete with real-life cautionary tales—stark reminders that tinkering with a gas furnace without proper knowledge or respect for its potential dangers is not just foolhardy but potentially fatal.

One such tale begins on a brisk November evening when John, an avid DIY enthusiast, noticed his furnace making unusual noises. With confidence bolstered by numerous successful home projects, he decided to embark on what he thought would be a straightforward repair job. Ignoring the furnace's warning label and overestimating his understanding of its workings, John proceeded to dismantle key components.

In another corner of town was Sarah who had watched several online tutorials and felt equipped to handle the pilot light issues plaguing her aging furnace. She too disregarded professional help, believing she could save time and money by handling it herself.

Both narratives converge on a common thread—a lack of appreciation for the intricate dance between fuel, flame, and exhaust that gas furnaces perform. John inadvertently disrupted this balance and caused a small leak. Unbeknownst to him, natural gas began seeping into his basement—a disaster waiting for an ignition source. Meanwhile, Sarah's attempts at fixing her pilot light failed to account for proper ventilation; the resulting poor combustion led to carbon monoxide buildup in her home.

These stories often reach their climax with either an emergency room visit due to toxic fume inhalation or even more tragically in some cases—an explosion that causes injury or property damage. Fortunately for John and Sarah, their tales served as stern warnings rather than epitaphs; they lived to tell their tales after neighbors raised alarms upon detecting the smell of gas and authorities intervened just in time.

The moral here is clear: mastering safe gas furnace repair is not merely about having the right tools or following instructions—it’s about recognizing one's limitations and understanding when professional assistance is paramount. Gas appliances require expertise not just because they're complex but because mistakes can have dire consequences.

Before embarking on any repair journey involving your gas furnace—or any other critical household appliance—take these real-life cautionary tales to heart:

1. Respect the complexity: Understand that furnaces are sophisticated systems requiring specialized knowledge.

2. Prioritize safety over savings: The cost saved by avoiding professional help pales in comparison to medical bills or reconstruction costs post-disaster.

3. Heed warnings: Manufacturer labels are there for a reason; they provide crucial information meant to prevent accidents.

4. Invest in regular maintenance: Have professionals inspect your system periodically to avoid needing emergency repairs.

Mastering Safe Gas Furnace Repair: A Cautionary Tale - heating system replacement

- furnace belt replacement

- heating system replacement

As we learn from these sobering stories—humility, caution, and safety must guide our actions when dealing with something as deceptively dangerous as a domesticated flame within our homes’ furnaces. Let us consider these tales not only as warnings but also as guides toward responsible homeownership where seeking expert advice isn't seen as defeat but rather intelligent foresight into preserving our well-being and sanctuaries we call home.