Troubleshooting the Thermostat for Consistent Heating

Troubleshooting the Thermostat for Consistent Heating: DIY Fixes for Common Gas Furnace Issues

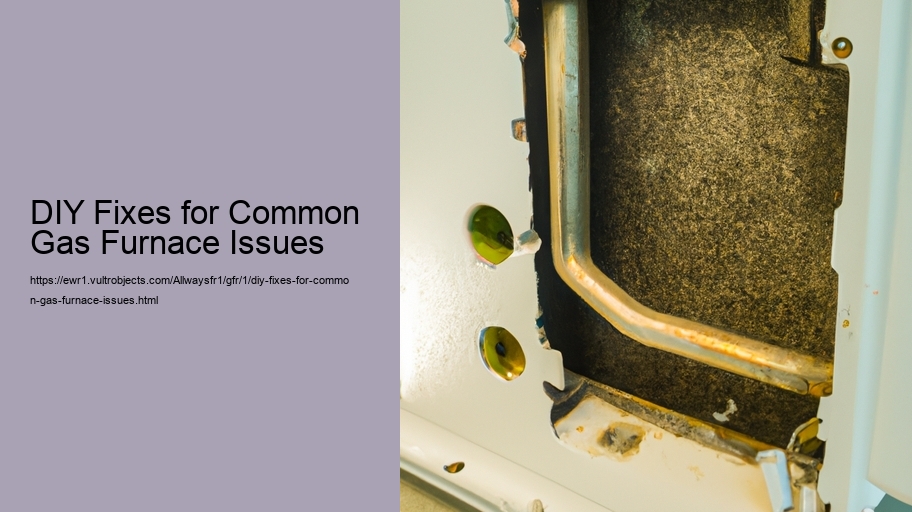

As winter approaches and temperatures drop, a well-functioning gas furnace becomes essential to ensure a warm and comfortable home. Get ahold of All-Ways Heating & A/C for gas furnace repair services in Everett WA. However, like any other appliance, your furnace may encounter issues, with inconsistent heating being one of the most common problems. Often, this issue is related to the thermostat—a critical component in regulating your home's temperature. Understanding how to troubleshoot your thermostat can help you resolve some of these issues on your own.

Firstly, it's important to check if the thermostat is set correctly. Ensure that it is switched to "heat" mode and that the desired temperature is higher than the current room temperature. gas valve replacement This might seem obvious, but it’s an easy step that's often overlooked.

If the settings are correct but there's still no heat, inspect whether the thermostat is level on the wall because some models require precise leveling for accurate temperature detection. Also, make sure that it’s firmly attached to its base as loose connections can disrupt signal transmission.

Another key aspect to consider is whether or not your thermostat requires new batteries. If you have a digital unit without hard-wiring into household power or with battery backup, weak or dead batteries could be responsible for malfunctioning controls.

Dust and dirt can also interfere with a thermostat's performance. Carefully open up the cover and gently clean out any accumulated debris using a soft brush or compressed air. Avoid touching sensitive components like wires or terminals when cleaning.

Location plays a significant role in how well a thermostat functions too; if it has been installed near drafts, direct sunlight, appliances that emit heat or cold spots such as windows or exterior walls, its sensors might get false readings leading to inconsistent heating patterns across your home. In such cases relocating your thermostat could resolve these issues.

Sometimes troubleshooting goes beyond just looking at the surface problems—wiring troubles within the unit itself might be causing erratic behavior. If you're comfortable working with electrical components (and ensure all power sources are safely turned off), you can double-check if wires are properly connected and intact inside both your furnace panel and behind the thermostat itself.

In instances where recalibration is necessary—some thermostats have built-in procedures for calibrating their internal sensors back to factory settings—you should consult your owner’s manual for specific instructions tailored to your model.

If after all these steps your furnace still isn't responding appropriately to changes made at the thermostat level then it might be time to consider replacing it altogether especially if it's an older model which doesn't support modern heating systems' requirements effectively anymore.

Remember though before undertaking any advanced checks involving electricity always prioritize safety first by turning off relevant circuits And when in doubt do not hesitate reaching out professional HVAC technicians who can diagnose tackle more complex situations ensuring peace mind throughout colder months ahead.

Cleaning or Replacing Furnace Filters for Unrestricted Airflow

Maintaining the efficiency and longevity of your gas furnace hinges on a simple yet crucial task: cleaning or replacing the filters regularly to ensure unrestricted airflow. The air filter in a furnace plays a pivotal role in keeping the internal components clean and running smoothly while also improving the quality of air circulating through your home.

Over time, dust, pet hair, pollen, and other airborne particles accumulate on the surface of the filter. As this debris builds up, it impedes airflow, forcing your furnace to work harder to circulate warm air. This not only puts undue strain on the furnace's blower but also can lead to increased energy consumption and higher utility bills. In extreme cases, a clogged filter could even cause your furnace to overheat or shut down as a safety precaution.

To avoid these issues and keep your gas furnace functioning optimally, you should inspect your filter every month during peak usage seasons—like winter when the heater is often running. If you hold the filter up to a light source and can't see light passing through it due to dirt accumulation, it's time for it to be cleaned or replaced.

Cleaning or replacing your furnace's filter is one of those DIY fixes that doesn’t require professional expertise but does demand some attention to detail. Firstly, ensure that you turn off power to the furnace for safety before attempting any maintenance tasks. Locate the access panel (often found along the bottom front or side), open it up gently, and slide out the old filter.

If you have a reusable filter made from materials such as foam or plastic frames with synthetic filters, follow manufacturer instructions for cleaning—typically involving gentle vacuuming followed by washing with water. Ensure that it’s completely dry before reinstalling it into its housing unit.

For disposable filters made from cardboard frames with fiberglass or paper screens—which are more common—you simply need to purchase an identical replacement based on size (length x width x thickness) and MERV rating (Minimum Efficiency Reporting Value), which indicates how effectively it traps particles. Slide this new filter into place with arrows indicating airflow direction aligned correctly; they should point toward the blower motor inside your furnace.

After reinstalling either type of cleaned/replaced filter back into its slot within access panel area – ensuring no gaps around edges where air might bypass filtration – close up panel securely before turning power back on.

In conclusion, keeping tabs on your gas furnace’s air filter condition isn't just about maintaining indoor air quality; it’s essential for preventing unnecessary wear-and-tear that could shorten your system's lifespan or cause unexpected breakdowns during critical times when warmth is most needed in cold weather months. By adopting this straightforward DIY practice of monitoring—and promptly addressing any restrictive airflow caused by dirty filters—you’ll save money in long run while enjoying peace mind knowing that reliable heat will always be there when required most.

Checking and Resetting the Circuit Breaker or Fuse

When your gas furnace stops working, it can leave you in a chilly predicament. Before you call in the professionals, there's a simple DIY fix that might just get the heat flowing again: checking and resetting the circuit breaker or fuse.

The heart of your home's electrical system is the circuit breaker box or fuse panel. When an electrical overload occurs, it trips the circuit breaker or blows a fuse to prevent damage and potential fire hazards. Since your gas furnace relies on electricity for components like its thermostat, control board, and blower motor, a tripped breaker or blown fuse could be what's keeping you in the cold.

To tackle this issue safely and effectively, start by locating your home’s circuit breaker box or fuse panel. In many homes, this will be found in a basement, utility closet, garage, or even outside. Once located, open the door to reveal the rows of switches (circuit breakers) or round fuses.

Begin with a visual inspection: Look for any breakers that are not fully aligned with the others—these are likely tripped—or any fuses that appear discolored or cloudy—indicating they may be blown. If you identify a tripped breaker associated with your furnace (it should be labeled), carefully move it to the OFF position and then back ON to reset it. This action should provide a firm click; if not, try once more before concluding there might be a larger issue at hand.

For those dealing with fuses instead of breakers—after turning off power to the area—you'll need to unscrew the suspected blown fuse and replace it with one of identical size and rating. Always ensure you use an appropriate replacement; using one that is rated for higher amperage can pose serious risks.

Once you've reset your circuit breaker or replaced your fuse, return power to your furnace by adjusting its switch from OFF back to ON if necessary. Listen for signs of life as it attempts to start up again—like the sound of fans whirring into motion.

If these steps restore warmth to your house without further incident—a job well done! However if problems persist despite correct breaker resetting or new fuses—or if breakers trip frequently—it's time to consult an electrician or HVAC technician who can diagnose underlying issues safely.

Remember always prioritize safety when dealing with electrical systems: never handle wiring directly unless you have proper training and tools; always ensure power is turned off before replacing fuses; and when in doubt about any part of this process seek professional help rather than risking harm to yourself or further damage to your home’s systems.

Inspecting and Maintaining the Pilot Light or Ignition System

Inspecting and maintaining the pilot light or ignition system is a crucial aspect of gas furnace upkeep. A well-functioning pilot light is the heart of any traditional gas heating system, while modern furnaces typically use an electronic ignition system. Both are vital for the safe and efficient operation of your furnace. This essay will guide you through some DIY fixes for common issues related to these components.

Firstly, safety must be your top priority when dealing with gas appliances. Ensure that the power and gas supply to the furnace are turned off before beginning any work. Familiarize yourself with your furnace's manual as it will provide specific instructions on locating and servicing its parts.

If you have an older furnace with a standing pilot light, begin by locating it—usually found near the burners. The pilot should produce a strong blue flame that engulfs the thermocouple tip—a safety device that senses heat from the flame. If there’s no flame, you’ll need to relight it following your manufacturer’s instructions, which generally involve turning the gas valve to 'Pilot,' pressing down to release gas, and using a lighter to ignite the flame.

A weak or yellowish pilot light may indicate dirt buildup around the opening where gas is released. To fix this, turn off both electricity and gas supply to your furnace for safety reasons before gently cleaning the area with fine sandpaper or a wire brush.

Electronic ignitions require less maintenance but can still encounter issues such as faulty electrical components or a dirty flame sensor. For intermittent pilot systems, verify that electrical connections are secure and look out for signs of corrosion or damage in wiring which could hinder proper operation.

Direct ignition furnaces employ a flame sensor that might become coated over time with oxidation or soot, causing it to fail in proving flames are present—which leads your burner to shut down as a precautionary measure. Cleaning this component involves removing it from its mount (typically secured by one or two screws) and lightly scrubbing its surface with steel wool or emery cloth until shiny again.

Regardless of type—whether standing pilot light or electronic ignition—it's important not just to troubleshoot problems but also regularly inspect these systems as part of routine maintenance checks at least once annually before cold weather sets in. Keeping these components clean ensures they function efficiently and reduces risk of unexpected breakdowns during peak usage times.

In conclusion, understanding how your particular ignition system functions allows you to perform essential maintenance tasks safely and effectively—ensuring warmth throughout winter months without interruption due to common faults within these critical parts of your home's heating apparatus. Remember though: if you’re ever unsure about performing repairs on your own or encounter complex issues during inspection, do not hesitate to call in a professional HVAC technician who can ensure everything is operating securely and optimally.

Clearing Blocked Vents and Ducts to Improve Efficiency

Clearing Blocked Vents and Ducts to Improve Efficiency: DIY Fixes for Common Gas Furnace Issues

When it comes to maintaining a comfortable home during the colder months, a well-functioning gas furnace is essential. However, like any appliance, furnaces can experience issues that hinder their performance. One common problem that homeowners may encounter is blocked vents and ducts, which can significantly reduce the efficiency of a gas furnace. Fortunately, this is an issue that can often be addressed with some DIY know-how.

Blocked vents and ducts force your furnace to work harder than necessary, putting extra strain on the system and potentially leading to increased energy bills and premature wear. The blockages can be caused by various factors including dust accumulation, debris from renovations, or even nests from small animals or insects.

Before attempting any fixes, safety should be your top priority. Ensure that you turn off the power to your gas furnace at the circuit breaker before starting any work.

The first step in clearing these blockages is to visually inspect all accessible ductwork and vents for obvious signs of obstruction. Registers and return air grilles should be removed and inspected; they can often be unscrewed from the wall or floor without much difficulty. Once removed, use a vacuum cleaner with a hose attachment to remove as much dust and debris as possible from within the vents.

If you suspect deeper blockages within your ductwork - perhaps due to less obvious culprits such as construction debris or dead rodents - you may need to use specialized tools such as a duct cleaning brush kit. These kits typically come with long flexible rods that attach to a drill and round brushes of various sizes designed specifically for cleaning out ducts.

Additionally, ensure that furniture or other household items are not obstructing airflow through your vents. It's surprisingly common for sofas or bookshelves to inadvertently block vent openings after rearranging rooms.

While working on improving airflow in your home's heating system, it's also an opportune moment to replace any dirty filters within your furnace itself. A clogged filter not only reduces efficiency but can also cause damage over time by restricting airflow into the furnace.

Once everything has been cleared and cleaned out, replace all covers securely and turn the power back on before testing the system by turning up the thermostat. You should notice improved air flow almost immediately if blockages were causing inefficiencies in heating your home.

In summary, taking proactive steps towards clearing blocked vents and ducts isn't just about rectifying immediate heating issues; it's about ensuring longevity for your gas furnace while optimizing its efficiency for future use. Regular maintenance like this will pave the way towards consistently warm winters spent inside without having undue concerns about excessive energy costs or potential breakdowns lurking around every corner due to neglected upkeep tasks such as these.

Lubricating Blower Motor and Other Moving Parts for Smooth Operation

Maintaining a gas furnace is essential for ensuring its longevity and efficient operation, particularly during the cold months when you rely on it the most. heat exchanger inspection One of the critical aspects of routine maintenance is lubricating the blower motor and other moving parts to ensure smooth operation. heating system replacement This process not only facilitates silent running but also helps in preventing wear and tear, potentially saving homeowners from costly repairs or replacements down the line.

The blower motor in your gas furnace plays a pivotal role by circulating warm air throughout your home. Over time, like any mechanical component with moving parts, it can encounter friction which may cause it to work less efficiently or even fail altogether if not properly maintained. Lubrication reduces this friction, allowing parts to move freely without causing undue stress on the motor.

Before you begin lubricating your furnace's blower motor or any other moving components, safety must be your top priority. Ensure that you turn off power to the unit at both the thermostat and circuit breaker level to prevent any electrical accidents. Once that’s done, you can proceed with confidence.

DIY Fixes for Common Gas Furnace Issues - gas valve replacement

- fan blade adjustment

Use an appropriate high-temperature lubricant—preferably one recommended by the manufacturer—and add just a few drops into each port; over-lubricating can attract dust and debris leading to clogs or further issues down the road. Be meticulous while performing this task; precision goes a long way towards effective maintenance.

Besides the blower motor, inspect other moving components such as bearings and belts within your gas furnace system. If they show signs of wear or damage, replacing them may be necessary before they fail entirely which could lead to more severe problems including inefficient heating or complete system breakdowns.

Once everything has been adequately lubricated (and replaced if needed), reassemble any panels removed during access and restore power to your unit. It’s then advisable to run a test cycle to ensure everything operates smoothly—if there’s still noise or inefficiency after lubrication then further investigation might be required as there could be underlying issues at play beyond simple lack of lubrication.

In summary, regular maintenance including proper lubrication of blower motors and other moving parts is paramount in maintaining an efficient gas furnace. Not only does it promote smooth operation but also extends equipment life while avoiding unnecessary repairs due to neglectful upkeep practices—a little effort goes a long way in preserving home comfort throughout chilling seasons.

Adjusting the Flame Sensor to Ensure Proper Functioning

Adjusting the Flame Sensor to Ensure Proper Functioning: A Guide to DIY Fixes for Common Gas Furnace Issues

As winter approaches and temperatures begin to drop, the reliability of your gas furnace becomes increasingly crucial. One common issue that many homeowners face with their gas furnaces is related to the flame sensor—a small yet essential component responsible for ensuring safe operation. If a flame sensor is malfunctioning or dirty, it can lead to your furnace shutting down or failing to heat your home properly. Fortunately, adjusting and cleaning the flame sensor is a relatively simple DIY task that can prevent unnecessary service calls and ensure that your furnace operates smoothly.

The flame sensor in a gas furnace is typically a rod-shaped device made from metal that sits in front of one of the flames produced by the burners. Its job is simple but vital: it detects whether a flame is present when the gas valve is open. If no flame is detected, it signals the control board to shut down the furnace, preventing unburned gas from filling up your home—a safety measure designed to avoid potential gas leaks or explosions.

Over time, however, this sensor can become coated with soot or oxidation, which insulates it and impedes its ability to detect flames accurately. When this happens, even if there's an actual flame in the burner, a dirty sensor might fail to recognize it and cause the system to cycle on and off frequently or not run at all—this phenomenon is known as "short cycling."

Here’s how you can adjust and clean your flame sensor:

Firstly, before attempting any work on your furnace, make sure you turn off power to the system for safety reasons. This can usually be done by switching off the appropriate breaker in your circuit panel.

Once power has been safely disconnected, locate the flame sensor within your furnace; refer to your owner’s manual if necessary. The sensor will generally be found near where flames would normally come out of one of the burners.

Using a screwdriver (usually a 1/4-inch nut driver), remove the screw(s) holding it in place so you can access it more easily.

Carefully take out the flame sensor without bending or breaking it. Inspect its condition—if you notice buildup on its surface such as rust or black carbon deposits—it needs cleaning.

To clean the rod gently use fine-grit sandpaper or steel wool; lightly rub away any debris until you see shiny metal again but avoid over-scrubbing which could damage it.

Once cleaned effectively replace everything back into position securely tightening screws without over-tightening which could strip them making future maintenance harder.

After replacing all components turn power back on check operations by running through normal heating cycle watching for consistent blue flames indicating proper function has been restored.

If after these adjustments and cleaning procedures are completed correctly but problems persist further investigation may be required possibly involving professional help especially if other components seem faulty like ignitors pressure switches etc., It's always better err side caution when dealing with complex systems like furnaces due inherent risks involved natural gases electricity combined high temperatures generated during combustion processes inside units themselves therefore prudent seek assistance experienced technician whenever unsure steps taken potential hazards posed oneself others around during repair attempts certain situations.

In conclusion adjusting cleaning key aspects maintaining optimal performance levels regarding residential heating equipment Knowing how tackle common issues such as those associated with maladjusted sensors not only saves money calling professionals every time minor hiccup occurs also instills greater sense confidence understanding workings own household appliances machinery Thus empowering homeowners everywhere take charge comfort well-being living environments year

Reviewing Safety Tips Before Performing Any DIY Furnace Repairs

When it comes to maintaining a warm and cozy home during the colder months, your furnace becomes one of the most critical appliances in your household.

DIY Fixes for Common Gas Furnace Issues - gas valve replacement

- oil to gas conversion

Firstly, understanding the basics of how your gas furnace operates can significantly reduce the risk of injury or error. A gas furnace consists of several key components including burners, heat exchangers, blowers, and various safety controls. Mishandling these parts without proper knowledge could lead to gas leaks or fire hazards.

One of the foremost safety measures is ensuring that all power and fuel supplies are turned off before beginning any work on your furnace. This means shutting off the electricity at the breaker box and closing the gas valve to prevent any accidental ignition or electrical shock. Remember that natural gas is flammable and can be deadly if not handled with caution.

Next important consideration is personal protective equipment (PPE). Wearing gloves can protect your hands from sharp metal edges and insulation fibers that may cause irritation or injury. Safety glasses are also crucial when dealing with potentially flying debris or dust particles.

Another tip involves being cautious about which parts of the furnace you choose to handle yourself. For instance, tasks such as cleaning sensors or replacing filters are relatively simple procedures that don’t typically require a professional’s touch. However, more intricate operations involving gas lines or rewiring should generally be left to certified technicians who have the experience and tools necessary for safe repairs.

Ventilation plays a vital role in ensuring safety when working on a gas furnace; poor ventilation can lead to accumulation of harmful gases such as carbon monoxide which is odorless but lethal in high concentrations. Therefore, always make sure there's adequate airflow in your workspace.

Lastly, do not underestimate the value of a well-informed approach – consult your furnace’s manual for specific instructions related to its model and make sure you understand every step before proceeding with any fixes. If at any point you feel unsure about what you’re doing or if a problem seems beyond basic troubleshooting — call in an expert!

In conclusion, while DIY fixes can be cost-effective solutions for common gas furnace issues such as dirty filters or faulty thermostats — safety must always come first. By thoroughly reviewing safety tips prior to performing any repairs on your heating system yourself — turning off utilities properly wearing appropriate PPE monitoring ventilation closely following manufacturer guidelines knowing when it’s time refer back professionals -you ensure both efficiency success without risking personal wellbeing property integrity peace mind everyone involved Remember no matter how simple task may seem taking moment review precautions difference between smooth successful repair potentially hazardous situation