Kitchen Disposal Repair Houston: Drain Line and P-Trap Solutions

A good disposer disappears into the background of a kitchen. It chews through scraps, keeps the sink moving, and stays quiet about it. When it stops, the whole room feels out of step. In Houston, where older bungalows share blocks with new builds, I see the same failure patterns play out across neighborhoods: a tired P-trap that never quite sealed, a drain line pitched the wrong way, a jammed impeller that cooked the motor, or a unit installed without accounting for the dishwasher line. The fix rarely lives inside the disposer alone. It lives in the plumbing that surrounds it.

This is a close look at how garbage disposals interact with the drain line and P-trap, why those pieces fail, and how to make solid repairs that last. I’ll also cover when to replace the unit, how to think about venting and code issues in Harris County and nearby jurisdictions, and what “Affordable Garbage disposal repair” actually means once parts, labor, and risk are accounted for.

How a disposal actually moves water

A disposal does not suck water. The impellers fling food against a grind ring, turning solids into slurry. Household water pressure and gravity do the transport. From the disposal’s side outlet, waste enters a short tailpiece or elbow, then the P-trap, then the wall stub. For everything to work, three things have to line up:

- The outlet needs to meet the P-trap inlet without strain or funky angles.

- The trap needs a consistent water seal and the right height.

- The drain line beyond the trap needs a real slope toward the main, not a belly that holds water.

When any of these is off by even a half inch, you get backups, persistent odors, and leaks that only show up when the dishwasher runs.

The P-trap is not optional

The P-trap is the water seal that blocks sewer gas and catches heavier debris before it hits the lateral. In Houston homes, I see traps made of ABS, PVC, or chrome-plated brass. Each has a place. PVC is forgiving and affordable. Brass looks sharp in exposed installs and has thinner walls that can help in tight cabinets, but it corrodes if the finish gets compromised. ABS is common in older houses. Mixing materials is fine with the right slip nuts and washers, but you need to respect diameters and transitions.

Trap size matters. Kitchen sinks typically run 1 1/2 inch trap assemblies. Step down to 1 1/4 and you’ll fight clogs. Step up without changing the rest of the branch and you lose velocity, which lets grease set up in the line. The trap arm, that short horizontal piece to the wall, needs a slight pitch, about a quarter inch per foot. Houston inspectors do not pull out a micrometer, but if the arm looks dead level, you are inviting sludge.

I often get called to replace a “bad disposal” that is perfectly fine. The trap is misaligned or the slip joint washers were installed backward. Those beveled washers have a thick and a thin edge. The bevel faces the flare. Get it wrong and the nut will tighten, but the joint weeps under dishwasher loads.

Dishwasher discharge, air gaps, and high loops

A disposal’s small side inlet is meant to receive the dishwasher discharge. The knockout plug inside that inlet must be removed before connecting the hose. More than once I’ve opened a cabinet to find a brand new hose clamped onto a solid plug. The dishwasher still runs, water has nowhere to go, and it burps back into the dishwasher tub or up through the sink.

Houston allows either a counter-mounted air gap or a high loop under the counter, subject to local enforcement and the dishwasher manufacturer’s requirements. Air gaps are foolproof and code-approved everywhere, but homeowners often dislike the look. A proper high loop rises to the underside of the countertop before dropping to the disposal, secured with a strap. That loop prevents sink water from siphoning into the dishwasher. Either method is better than a sagging hose that sits below the disposal inlet and traps foul water.

Why Houston kitchens see repeated clogs

Local water chemistry and cooking habits contribute. Houston’s water typically falls on the softer side, which doesn’t create scale like in central Texas, but we cook with oil, and a lot of it. Grease behaves nicely when hot, then coats the pipe as it cools. Ranch houses with long, low kitchen runs toward the back of the house are notorious for flat spots. The line might run twenty feet before it turns down to meet the main. If that run wasn’t installed with a true quarter-inch-per-foot slope, it sags between hangers. Grease and coffee grounds settle right there.

Garbage disposals do not “eat” grease. They may move it a foot or two, but they also emulsify it just enough to carry it into the first cold section of pipe where it re-solidifies. That is why trap replacement alone doesn’t fix recurring clogs. You have to evaluate the whole run.

Diagnosing the real fault

Start with the symptoms. A hum and no spin points to a jam or a seized motor. Slow drainage points to a trap or line obstruction. Leaks while the unit is off usually trace to the sink flange or the discharge elbow. Leaks only when the dishwasher runs point to the dishwasher inlet or a loose high loop.

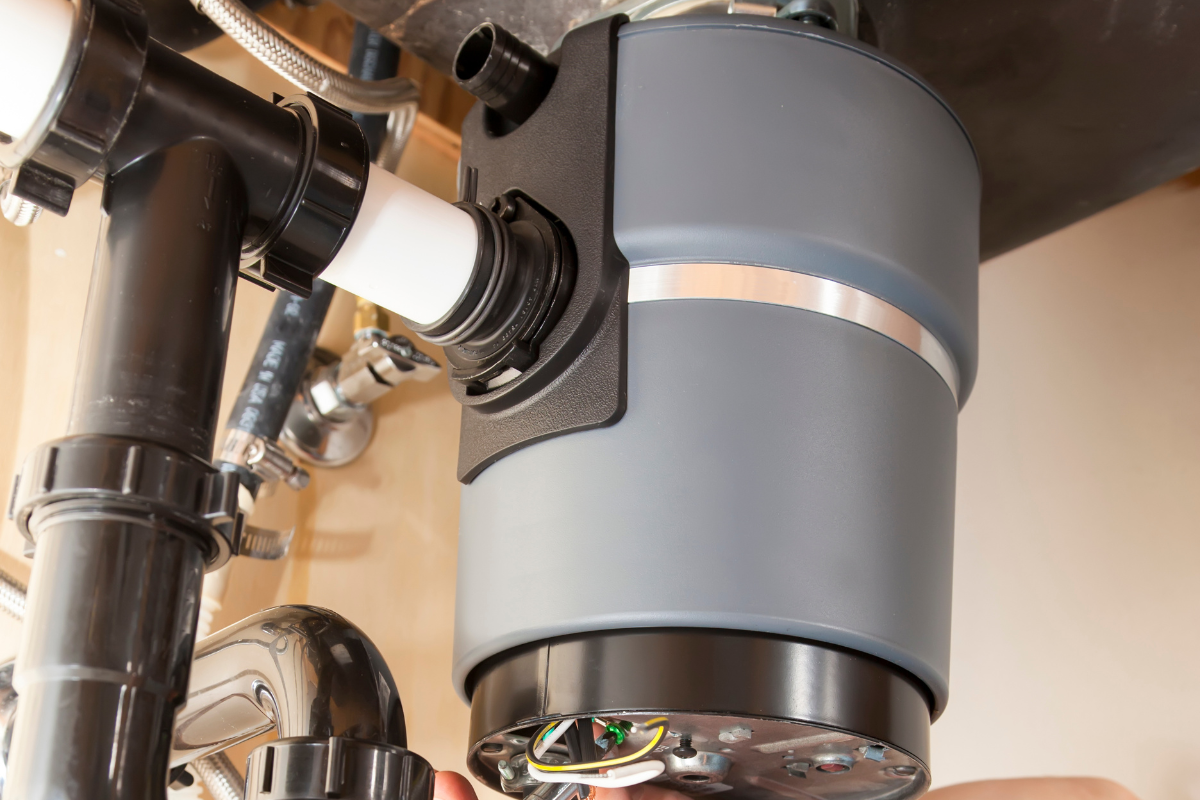

When I’m called for Kitchen disposal repair Houston homeowners can count on, I bring a small set of specific tools: a drop light, a mirror, plumber’s putty, a selection of slip joint washers, a 1 1/2 inch schedule 40 trap kit, garbage disposal installation reducer bushings, a spinner for the sink flange, and a flexible tailpiece with a gentle bend. I also carry a hand auger and, for newer PVC, a compact camera. The goal is to prove whether the problem lives at the sink or deeper in the line before I quote anything beyond an affordable service minimum.

Here is a simple field test that reveals a lot: remove the trap and trap arm, set a bucket under the wall stub, and pour two gallons of water from the sink basin through a straight temporary tailpiece. If flow is strong and continuous, your issue likely lives in the trap geometry or the disposer itself. If the wall stub belches or backs up into your bucket, the line needs cleaning or re-pitching.

Repairing or re-plumbing the trap

Most homeowners can handle a trap rebuild if there is adequate room. The key is to avoid a forced fit. If you have to pull the disposal sideways to meet the trap, you are preloading the joint and inviting a leak later.

A professional approach follows a simple sequence:

- Dry fit the parts. With the disposal sitting square, align the discharge elbow to a trap that meets the wall stub without twisting the components. If the wall stub is too high or low, use a tailpiece extension and a shallow trap or a longer trap arm to land plane. Avoid accordion-style flex pipes except as a temporary measure. They catch debris and whistle under flow.

- Build from the sink down. Set the sink flange, secure the mounting ring, then hang the disposal. Only then cut the trap arm to length. The trap weir, the high point inside the trap, should sit below the wall stub outlet. A trap that is higher than the stub will siphon or burp.

- Place washers correctly. Beveled washers face the flare, flat washers go under nuts that seal to a flat surface. Hand-tighten, then give a quarter turn with pliers. Over-tightening deforms the washer and cracks thin-walled PVC nuts.

- Water test with tissue. Wipe every joint dry, then run hot water and the dishwasher if connected. Lay a strip of tissue under each joint. Even a slow weep will print as a wet line within a minute.

That sequence prevents 90 percent of nuisance leaks I see after DIY attempts.

When the drain line is the culprit

If the line beyond the trap is the issue, you have choices. Snaking can open a path, but if you pull back fat and coffee grounds every six months, you are treating symptoms. I recommend hydro-jetting for lines with heavy grease, especially in restaurants and in homes where a long kitchen branch ties into the main under the slab. Jetting scours the walls of the pipe. It costs more than cabling, but you go longer between service calls.

Slope correction is trickier. If the sag happens in the cabinet or the first couple feet, you can repitch by changing the trap arm and adding a proper escutcheon and coupling at the wall. If the sag is inside the wall or under the slab, you are into a larger project. I’ve opened drywall to strap a horizontal run and picked up a consistent quarter-inch-per-foot pitch over six feet. Under-slab bellies require tunneling or rerouting, and that is a conversation about budget, risk, and house value.

I get asked about chemical drain cleaners. Skip them. Caustics can soften old ABS and eat chrome plating, and they never fix a pitch problem. Enzyme treatments help maintain a clean line after a proper mechanical cleaning, but they are not magic.

Common installation mistakes that trigger callbacks

Two patterns stand out in Houston’s mix of older plumbing and big-box disposers.

First, using the wrong discharge elbow length. Many disposers ship with a straight discharge that sits too low or too far back for the existing trap. The quick fix is a flex trap. It works for a bit, then starts catching pulp. A better fix is to use a longer tailpiece, a 45-degree slip joint elbow, or an offset basket strainer on the sink to move the drop point. Getting alignment right on day one prevents recurring service calls.

Second, ignoring venting. A kitchen branch without proper venting will gurgle, siphon the trap, and smell. Houston code permits air admittance valves in certain remodel cases, but they have to be accessible and rated. I’ve opened cabinets to find a cheap AAV buried behind a fixed panel. If your sink glugs after the disposal stops, suspect venting. An AAV will quiet the line if there is no easy path to tie into an existing vent. It is not a cure-all, but it is better than a dry trap.

Repair vs replacement: how to decide

Not every jammed unit should be replaced, and not every old unit deserves a rescue. Consider age, housing, and usage. If a disposal is over ten years old, rusted at the seams, or trips the reset with normal loads, it is living on borrowed time. Replacing it with a midrange, sound-insulated unit saves labor on future repairs and usually brings quieter operation.

On the other hand, if a three-year-old unit hums and trips, it may only need a flywheel freed with an offset wrench and the thermal protector reset. You can often hear the difference. A sharp buzz that stops quickly suggests the thermal overload is saving the motor from damage. A low, grinding growl suggests a foreign object wedged inside. Turn off power, use a flashlight and tongs, never your fingers, to retrieve the culprit.

Homeowners call asking for “Affordable Garbage disposal repair” and expect a single number. The real cost depends on how much time we spend on the plumbing around the unit. A straightforward Garbage disposal repair may run a modest service charge plus parts, while adding a new trap assembly, dishwasher air gap, and camera inspection moves it into a different tier. Clear estimates, with line items for the disposal, P-trap, and drain line work, help avoid surprises.

Selecting the right unit for Houston kitchens

Brands matter less than build quality and size. Stainless grind components hold up better with citrus and ice. Sound insulation is worth the price if the kitchen opens to the living area. Horsepower should match the household. A 1/2 HP unit handles a small apartment with light use. A family that cooks daily and runs a dishwasher twice a day is better served by 3/4 or 1 HP with multi-stage grinding. Bigger units are also heavier, which means the sink flange and mounting system need to be properly set with a full ring of plumber’s putty. Skimp on putty, and you’ll chase a slow seep that stains the cabinet floor.

If you are considering Garbage disposal installation Houston homeowners often choose units that advertise jam-sense or auto-reverse features. Those can buy you time, but they are not a substitute for good plumbing. I’d rather see a standard unit with a clean, correctly pitched drain than a premium unit feeding a flat line.

The little details that prevent big headaches

A few small practices make a large difference. When connecting the dishwasher, secure the hose with a proper clamp and ensure the high loop is above the flood rim of the sink if you forgo an air gap. Use stainless worm clamps, not spring clips that lose tension. When you tighten the disposer’s discharge elbow, use a fiber gasket and orient the elbow to avoid straining the trap. After tightening slip nuts, mark their position with a pencil. If a joint starts to back off over time, you have a reference.

Add a GFCI where required. Many older Houston kitchens have disposers on shared circuits with dishwashers. A dedicated circuit is ideal, but not always practical in a retrofit. At least ensure the wire size and breaker match the load and that your switch is rated for motor duty. Loose connections cause heat, which can cook the insulation in that tight cabinet.

Finally, take odors seriously. If a sink smells even after a trap rebuild, clean the rubber baffle at the top of the disposal. It traps biofilm. Pull it, scrub with dish soap and a brush, and rinse. Run a tray of ice with a cup of rock salt to scour the chamber. Citrus peels freshen the air but do not replace cleaning.

What a thorough service call looks like

A professional visit should feel methodical, not rushed. A good tech will listen to your history, check for leaks, test the dishwasher discharge, inspect the trap alignment, and verify the outlet’s wiring and grounding. If the line is suspect, they should explain the difference between snaking and jetting, with prices and expected outcomes. If you ask about replacement, you should hear trade-offs between horsepower, noise, and cabinet space, with a unit sized to your use, not just what is on the truck.

I keep small stock of common units in the service vehicle, but I do not force a model. If your sink has a shallow bowl or an apron-front design, clearance can be tight. Measuring first avoids returns. I’ve had jobs where we gained a critical inch by swapping a deep basket strainer for a low-profile flange or by rotating the disposer 90 degrees to align with a better trap path.

Preventive habits that actually help

You can avoid most clogs with realistic habits. Keep fibrous materials out. Celery strings, onion skins, and corn silk wrap around the impellers. Potato peels combine with grease to make a paste. Use the disposer as a finishing tool after you scrape plates, not a primary trash can. Always run a strong stream of cold water before, during, and after grinding. Cold water helps keep fats solid long enough to move past the trap. Hot water can soften a clog and mask poor flow during the grind, only to let grease set downstream when you shut the tap.

Once a month, pull the baffle and clean it. If you use the dishwasher heavily, check the high loop or air gap during spring cleaning. A removed obstruction there prevents backflow. And every time you look under the sink, glance at the cabinet floor. Swollen particleboard tells a story earlier than a drip will.

A note on code and permits

Most disposal swaps in Houston do not require a permit if you are doing like-for-like with no changes to the drain line. Once you alter the trap or reroute the drain, you step into plumbing work that may require a permit, especially in incorporated areas and municipalities like Bellaire or West U. Licensed plumbers know where the line is drawn and when to pull a permit. A permitted job protects you when you sell the house and keeps insurance adjusters from pointing to unpermitted work after a leak.

If you are in a high-rise or a building with a common waste stack, check HOA rules. Many towers restrict disposers or specify models. In those buildings, a blockage can impact neighbors below you. The fines for a flood outweigh any savings from a quick, unreviewed install.

When you need help and what “affordable” really means

There is a point where DIY effort crosses into diminishing returns. If you have rebuilt the trap twice and still smell sewer gas, call someone. If the line backs up every holiday, have it jetted and camera inspected. If your disposal chews loudly and spits water when the dishwasher runs, the plumbing needs a trained eye.

Affordable Garbage disposal repair is not the cheapest number on a postcard. It is work done once, with parts that last, and a clear explanation of what you are paying for. A fair ticket in Houston for basic Garbage disposal repair covers the service call, diagnosis, minor parts like washers and a trap kit, and a test cycle with the dishwasher. Installation of a new unit is typically priced separately, with options ranging from budget units to quieter, higher horsepower models. When you search for Kitchen disposal repair Houston services, ask for specifics about drain line evaluation and P-trap adjustments in addition to the unit itself. That is where the long-term value lives.

A short path to peace and quiet

A quiet, odor-free sink is not complicated, but it is precise. The disposer needs to be solidly hung, the P-trap set with the right geometry, the drain line pitched and clear, and the dishwasher discharge managed correctly. The details add up. That is why a twenty-minute fix sometimes turns into a two-hour rebuild, and why you want a tech who will tell you that before the work begins.

If you are planning a remodel or replacing a sink, this is the perfect time to correct a finicky drain. Adjusting the height of the wall stub, adding a proper vent tie-in, and selecting a disposer that fits your cabinet will make years of daily use uneventful. If you are in a maintenance mindset, schedule a cleaning before the holidays and avoid the crunch when every service truck in Houston is busy rescuing kitchens from gravy and potato peels.

Whether you need straightforward Garbage disposal repair or a full Garbage disposal installation Houston homeowners can trust, treat the drain line and P-trap as part of the same system. Fix them together, and your disposer will go back to doing what it does best: disappearing into the background.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600