Houston’s Trusted Experts for Garbage Disposal Repair

Houston kitchens work hard. Families cook more at home than ever, restaurants hustle through lunch and dinner rushes, and even office break rooms see a steady stream of coffee grounds and salad trimmings. The quiet workhorse under many of those sinks is the garbage disposal. It hums along, day after day, until one afternoon it does not. Maybe it kitchen sink disposal installation jams with a rattle that makes you back away, or it quits without a sound and leaves the sink full of gray water. When that happens, your first thought is often timing. Can someone get here today? The second is trust. Will the tech diagnose it straight and fix only what’s needed?

That combination, quick response and honest repair, is what separates reliable service from a gamble. The best teams in Houston combine practical experience with the judgment to know when to repair, when to rebuild, and when to replace a unit with something that fits your sink, your electrical circuit, and your budget. I have worked in enough Houston homes to see both the easy fixes and the head-scratchers, and the difference it makes when a homeowner has a clear explanation before authorizing a repair.

The role of a disposal in a Houston kitchen

A disposal is not a food processor. It is a controlled grinder that breaks down small food scraps and sends them along with water into the drain line. In a city like Houston, where many houses sit on slab foundations and lines can run long distances, that last part matters. Water is the vehicle. If a disposal works but the drain is slow, you will still end up with standing water and an unhappy sink.

Homes in Montrose with original cast iron drains behave differently than newer copper and PVC setups in the suburbs. Restaurant disposals face bones, pits, and a stream of fibrous waste that would overwhelm a residential unit. Even within homes, choices matter. A 1/3 horsepower unit might be fine for a small apartment with light cooking, while a family that hosts weekly dinners will be happier with a 3/4 or 1 horsepower model with better torque and stainless components.

Understanding the context helps us advise on realistic expectations. When residents call asking for Affordable Garbage disposal repair, the most cost-effective answer might be a targeted fix, but sometimes the right move is a replacement that avoids another service call two months later.

What often goes wrong, and why

Most disposal problems fall into repeatable patterns. The trick is teasing out the cause without throwing parts at the issue. A few examples I have seen again and again in Houston:

A disposal that hums but does not spin typically has a jam or a stuck impeller plate. Maybe a teaspoon slipped in and wedged against the grind ring, or celery fibers have wrapped around the impellers. The reset button will not help here. A hex key in the bottom service port usually frees it. If it loosens up and spins freely by hand, odds are good it will run once the jam clears. A tech will also check for motor overheating that can mimic a jam.

A dead disposal with no sound at all often points to a tripped internal breaker or a dead wall switch. Pressing the red reset button on the bottom can bring it back, but if it trips again, there is a reason. Overheating due to a stalled rotor, water intrusion into the motor housing from a failed seal, or a failing capacitor can all cause repeat trips. Good practice is to reset once, test under light load, and investigate further if it trips again.

Leaks fall into three common zones. A leak from the bottom center of the housing usually means the shaft seal has failed, and that is not a field-repair part for most units. That is generally replacement territory. A leak at the sink flange points to a loose mounting ring or dried plumber’s putty. A leak at the dishwasher inlet or discharge elbow is usually a hose, clamp, or gasket issue. I have tightened dozens of clamps that cured a “mystery leak” in five minutes.

Foul odors are not a sign of a dying motor, they are a sign of buildup. Fatty film on the splash guard and grind chamber traps smells. Running ice or citrus rinds feels satisfying but mostly perfumed the air. The real fix is cleaning the baffle and chamber walls, then flushing with hot water. If the sink is double-bowl with a shared trap, biofilm in the trap can contribute too.

Slow draining with a working unit means the downstream line is restricted. When homeowners say the disposal sounds fine but water sits in the sink, the culprit is almost always in the trap or the horizontal run in the wall, especially if rice, pasta, or coffee grounds have been frequent guests. Mechanical clearing usually solves it. Using chemicals in a disposal rarely ends well, and some manufacturers will void warranties if caustics are used.

These patterns never get old for a reason. They reflect the physics of how disposals spin and how drain lines move water. A seasoned tech in Houston can walk in, listen, tap a few spots, check the switch and outlet, and have a good idea of the fix in minutes.

Affordable Garbage disposal repair without cutting corners

Price is never the only variable, but it is always a variable. When homeowners search for Affordable Garbage disposal repair, they are usually trying to avoid two things: surprise add-ons and short-lived fixes. Transparent pricing means quoting for diagnosis, then explaining part costs and labor before proceeding. On my teams, we treat the first 15 to 30 minutes as a diagnostic window. If we suspect a replacement might be smarter than repair, we say so before we bill for a repair you may not want.

Trade-offs are real. Rebuilding a switch or replacing a capacitor can extend a unit’s life for another year or two, but if you can hear bearing noise, the motor is on its way out, and money spent now may only postpone a replacement. Conversely, replacing a unit because it jammed once makes little sense. A jam is a use issue, not a death sentence.

For landlords and property managers, the calculus is different. A reliable mid-grade model with stainless components often costs less over five years compared to repeated service calls on builder-grade units. Documenting disposal model, install date, and any adjustments (like adding an air gap for the dishwasher line) helps track predictable failures and budget accurately.

When a repair makes sense, and when to replace

A large share of service visits end with a straightforward repair. Rewiring a loose connection at the wall switch, resetting a tripped unit after clearing a jam, tightening the mounting ring, replacing a discharge gasket, or pulling a foreign object are all reasonable fixes.

Replacement is the better call when the motor housing leaks, the unit trips its internal breaker repeatedly despite clear flow, the bearings growl, or the impeller plate wobbles. Age matters. Once a disposal passes the 8 to 10 year mark in a typical Houston home, corrosion inside the housing often accelerates. If water has crossed into the motor compartment, replacement is safer and ultimately cheaper.

The other trigger for replacement is a mismatch to the household. If you are running a 1/3 horsepower unit under a farmhouse sink for a family of six that cooks nightly, a string of service calls is not a surprise. Upgrading to 3/4 or 1 horsepower with better anti-vibration mounts and stainless impellers will reduce jams and noise. If you run a dishwasher into the disposal, look for a model with a proper dishwasher inlet and space to add a high loop or air gap depending on your setup.

The process of getting it right the first time

For homeowners, a clear process reduces stress. When we handle a service call, we start with a quick interview. What were you doing when it failed? Did it hum, click, or go silent? Any leaks under the sink? Has the breaker panel tripped? Those answers guide what we check first. Next we inspect the outlet, switch, and wiring. A non-contact tester confirms power at the switch. We verify the reset button and check for free rotation with the hex key.

If the jam clears and the unit runs smoothly, we still run water for several minutes and test the drain. If disassembly is needed, we protect the cabinet, set a tray for screws, and take photos of the pre-existing plumbing to return everything to the same orientation. After finishing, we run paper towels around connections to check for slow weeps that can be missed by a quick glance. We also run the dishwasher briefly if it ties into the disposal, since some leaks only show under that flow.

When it is a replacement job, the extra steps matter. We measure the cabinet height to ensure the new unit clears the shelf or P-trap, confirm the electrical is either plug-in or hardwired as needed, and match the sink flange finish to your hardware. A standard install in Houston often runs 60 to 90 minutes including disposal of the old unit. Complications like offset drains, double traps that need correction, or corroded flanges can add time, and it is best to discuss that before we start.

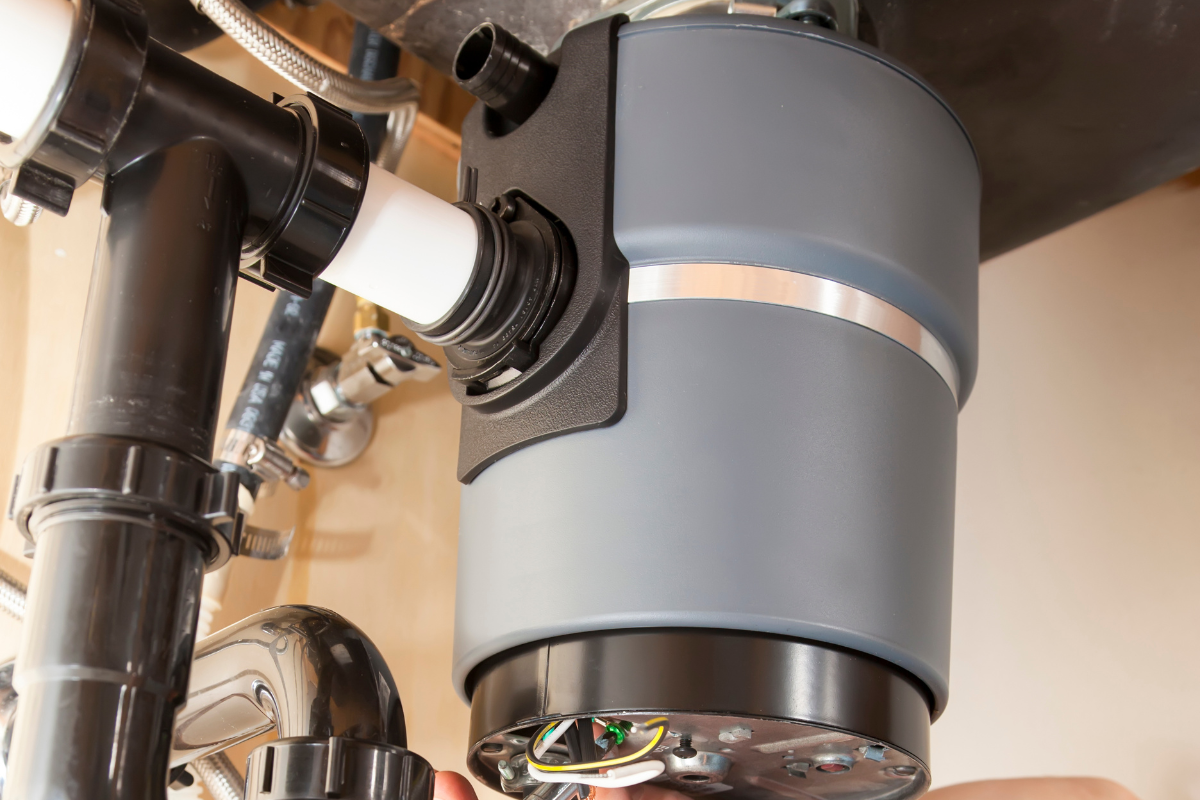

Garbage disposal installation Houston homeowners can trust

Good installation pays for itself. Misaligned discharge elbows or over-tightened PVC can create stresses that show up as leaks months later. Proper plumbers putty at the sink flange, torqued in stages, avoids a warped seal. The mounting ring needs to be fully engaged, not just close. With composite or fireclay sinks, I prefer a flanged adapter designed for the sink type, since some materials can chip if the standard metal clamp bites unevenly.

Electrical safety is non-negotiable. If a disposal is hardwired, the connection should be in a junction box with stainless steel disposal components a proper strain relief. If it is a corded unit, the receptacle under the sink should be grounded and protected, often on a GFCI. I have replaced plenty of cords scorched by loose plug connections. If your dishwasher shares the circuit and you regularly trip the breaker, a simple panel upgrade to split loads can make daily life quieter and safer.

For Kitchen disposal repair Houston residents also benefit from a quick check of related parts. The baffle or splash guard, especially on older units, stiffens over time and traps food. Swapping to a removable guard improves cleaning and odor control. If your dishwasher drains into the disposal, adding a high loop or air gap reduces backflow and meets code in many jurisdictions. These are small details that save headaches later.

Caring for your disposal between service visits

There are daily habits that keep a disposal healthy. Run cold water before you turn it on, keep the water running while it grinds, then let it run another 10 to 20 seconds afterward. Water carries scraps away. Cold, not hot, keeps fats congealed so they pass into the drain instead of coating the chamber and lines. Avoid fibrous and starchy materials in bulk. A little is fine, a handful of onion skins or a pot of mashed potatoes will create trouble.

Clean the splash guard. That single task eliminates most odors. Pull it out if it is removable, otherwise scrub it in place with a brush and a small amount of dish soap. Once a month, toss in a cup of ice and a spoon of rock salt to knock residue off the chamber emergency garbage disposal repair walls. This does not sharpen blades, since disposals do not have blades, but it does clean the surfaces that smell.

If you hear a change in sound, address it early. A light rattle could be a metal tab or bottle cap bouncing around the chamber. Turn the unit off, unplug or switch off power, and retrieve it with pliers. Do not fish around with your hand. If it hums and trips, let it cool for a few minutes before resetting. Repeated resets without diagnosing the cause can burn out a motor that would otherwise be fine.

Matching models and features to how you cook

When the conversation shifts from repair to replacement, the market can feel crowded. Within the mainstream brands, performance differences come down to motor size, grind stage design, materials, and noise control. For most Houston homeowners, a 3/4 horsepower model with stainless grind components provides an excellent mix of power and durability. If you cook heavy meals nightly, step to 1 horsepower. If you live in a small apartment and cook lightly, a compact 1/2 horsepower unit might be the best fit to save space.

Noise ratings matter, but the mounting and cabinet build influence noise as much as the motor. Rubber isolators at the mounting ring, anti-vibration tailpieces, and a well-secured sink reduce resonance. If you have a thin stainless sink that drums loudly, adding sound pads helps more than you would expect.

Look closely at the warranty. A 4 to 7 year warranty on parts and in-home service is typical for mid to upper models. If the warranty requires professional installation to be valid, keep your invoice. When comparing prices for Garbage disposal installation Houston wide, factor in that warranty value, not just the initial install fee.

The Houston-specific gotchas

Every city has quirks. In Houston, water hardness varies, and while it does not directly damage a disposal, it can contribute to scale buildup around seals and the sink flange. Running a quick wipe of the flange after heavy sink use reduces mineral rings that turn into weeps later.

Many neighborhoods have older electrical panels with limited spare circuits. It is tempting to piggyback the disposal on whatever is handy. Over time, that leads to nuisance trips. If we see that during a service call, we raise it. Separating the disposal and dishwasher or putting them on an appropriately sized shared circuit prevents callbacks.

Storm-related power flickers are another local reality. A disposal that was mid-cycle during a power dip can stall and overheat when the power returns. If your lights flickered and the disposal now hums or is dead, start with the reset button, then check for jams at the hex key. If it still trips, let it cool and call for service. I have replaced several units after late-night storm resets where the motor cooked itself because it was restarted against a jam.

How to choose a service provider you will use again

You want a team that treats your kitchen like their own. Experience shows up in small behaviors: laying a mat in front of the sink, vacuuming a trap after clearing a clog, labeling a junction box after wiring a new unit. Ask about their diagnostic process, whether they carry common gaskets, guards, and electrical cords on the truck, and how they handle situations where a repair turns into a replacement mid-visit.

Response time matters, but accuracy matters more. A tech who returns your sink to service in one visit because they anticipated parts and had a realistic plan saves you both money and time. If you are on a budget, say it. A steady company can prioritize repairs that restore function today and schedule non-critical improvements later, like replacing an aging baffle or adding a dedicated outlet.

Finally, check that they explain what failed in plain terms and hand over simple care instructions. The best service is the one you do not need again for a long while.

A short homeowner checklist for smarter calls

- Note the symptom: humming, silence, leak, smell, or slow drain.

- Check the reset button and the wall switch, once, without repeated cycles.

- Look under the sink for obvious leaks or disconnected hoses.

- Confirm power at the outlet with another device if it is a plug-in unit.

- Share model and approximate age with the tech when you call.

That small set of details helps a technician arrive prepared, which often reduces total cost.

For restaurants and commercial kitchens

Commercial disposals are a different animal. They run longer hours and face harder waste. I have seen pits chew up impellers in a month when staff assumed the unit could handle bone fragments like a grinder. Training staff matters as much as gear selection. Use strainers to catch flatware, schedule regular maintenance flushes, and consider adding a solids interceptor upstream of the trap. Service schedules for commercial units make sense quarterly or semi-annually, depending on volume. If your grease trap backs up, it will show at the disposal first. Fixing that upstream issue saves more than any number of disposal repairs.

The value of straight talk

Garbage disposal repair is not glamorous. It is practical and specific. Homeowners want the sink to drain, the unit to run quietly, and the cabinet to stay dry. When we approach repairs with clear diagnostics, cost transparency, and respect for how people actually cook and clean, we earn repeat business the right way. Whether you need quick Kitchen disposal repair Houston wide, a measured opinion on whether to repair or replace, or a clean, code-compliant install on a new sink, the work pays off every time you flip the switch and hear that smooth, confident hum.

Good service, at a fair price, with care for the details you do not want to think about. That is what trusted experts deliver. And when you know who to call, a broken disposal is a short hiccup, not a kitchen crisis.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600