Electrical Repair Services Houston: Inspections and Safety Checks

Electrical systems rarely fail without sending a warning first. A light flicker that coincides with the AC kicking on, a breaker that feels warm, a faint buzz at a switch, that occasional burnt-dust smell when the dryer runs. In Houston’s climate, those hints arrive sooner and more often than many homeowners expect. Heat, humidity, and heavy seasonal loads strain wiring, connections, and equipment. Add older construction, renovations layered over renovations, and a wide mix of utility infrastructure, and you have a city where inspections and safety checks are not a nice-to-have, but a practical necessity.

I work homes that range from 1940s bungalows in the Heights to newer builds along the Grand Parkway. The problems differ, yet the pattern is consistent: owners call for electrical repair when something stops working. The smarter move is to schedule and prioritize inspections that prevent emergencies, not just react when they arrive. The value isn’t abstract. A proper check might catch a loose neutral that has quietly been baking a connection for months, or uncover a double-tapped breaker that passed unnoticed during a quick flip renovation. Both can escalate into property damage or injury.

Why inspections in Houston need a Houston approach

A generic checklist misses the local stressors. Our grid sees summer peaks that keep compressors and air handlers running nearly nonstop. Attics turn into ovens. Panels sweat. Even buried conductors see soil movement during periods of heavy rain then drought. I see corrosion at service lugs more often here than in drier regions. Aluminum branch circuits from the late 60s and early 70s are still around in some neighborhoods, and they age poorly when terminals expand and contract in our heat.

A good electrician in Houston balances code compliance with climate realities. The National Electrical Code sets the floor. Local conditions push you to exceed it where it makes sense. That might mean upgrading the service entrance conductors, elevating outdoor equipment above flood risk, selecting corrosion-resistant fittings, or planning for whole-home surge protection because of frequent storms. It also means pacing inspections around the seasons. Checking a system in May before summer loads spike can prevent expensive calls in August.

What a thorough safety check actually covers

Many homeowners expect a glance at the panel and a few outlet tests. A real safety check for residential electrical repair goes deeper. The sequence matters because it builds context before chasing symptoms.

Start at the service. Confirm the meter base integrity, service drop or lateral condition, drip loops, and bonding. In older homes, I often find original lugs that have been tightened repeatedly but never cleaned. Oxidation increases resistance, which turns into heat under high load. In humid months you may see greenish corrosion, in drier months a powdery white bloom on aluminum.

At the main panel, a competent technician verifies labeling, breaker sizing, torque on lugs, bus condition, neutral and ground separation where required, bonding jumpers, and the presence and rating of the main disconnect. We test GFCI and AFCI protection where code requires it, and we often recommend extending protection into areas where code didn’t require it when the home was built. If the house has a split-bus panel or obsolete equipment like certain recalled Stab-Lok models, replacement gets top priority. Electrical panel repair can be piecemeal on newer equipment, but with obsolete or damaged gear, replacement is both safer and more cost effective.

From there, branch circuits deserve methodical attention. We test representative outlets and switches on each circuit rather than relying on a plug-in tester alone. Thermal imaging, when done by someone who knows how to interpret it, helps locate loose terminations without tearing open walls. I’ve found hotspots at backstabbed receptacles behind fridges that never tripped a breaker but were one holiday party away from failure. For electrical wiring repair, the small corrections are often the big wins: moving a conductor from a spring backstab to a screw terminal, shortening and re-terminating scorched pigtails, or replacing a worn receptacle whose tension can no longer hold a plug.

Large appliances and HVAC equipment reveal issues that basic inspections miss. A heat pump that starts hard can dim lights and stress a marginal connection upstream. Water heaters and ranges frequently share outdated breakers from a prior remodel. In flood-prone parts of the city, I check every splice, junction box, and low point in conduit for signs of past water intrusion. If you see rust flakes in a panel, there is a story behind them that needs to be understood, not wiped away.

Light fixtures, fans, and exterior circuits also earn attention. Fan boxes must be rated and mounted correctly, and I routinely find older boxes that were never designed for a 70-inch fan. Exterior outlets are notorious for missing in-use covers or worn gaskets. A GFCI that trips on a patio might be less about the device and more about intermittent moisture electrical repair services in the box. Landscape lighting transformers, if not protected with the right overcurrent device, can mask faults and slowly cook insulation.

Earthing and bonding make or break a system under fault conditions. Houston soil conductivity varies, and ground rod connections fail quietly. A quick clamp over an oxidized rod might pass a casual look, but a real inspection measures continuity, evaluates connections, and verifies bonding to metal water piping where present. Surge protective devices work best on a system with solid bonding. They are not a cure-all for a weak grounding electrode system.

The anatomy of a panel evaluation

Panels tell the story of a home’s electrical life. I look for heat discoloration on bus bars, signs of arcing at breaker stabs, and evidence of moisture ingress at the top. Double-lugged neutrals remain common in older installations where multiple neutrals share a terminal that was designed for only one conductor. It seems minor until a neutral loosens and a multiwire branch circuit starts misbehaving with voltage swings that fry electronics.

Gauge mismatches show up often during home electrical repair when circuits were extended by a non-professional. A 20-amp breaker feeding a stretch of 14 AWG wire hides behind drywall until it doesn’t. Likewise, tandem breakers installed where the panel isn’t listed for them can overload the bus and create clearance issues. Panels located in closets or bathrooms, which was once permitted in some jurisdictions, now need relocation for compliance and safety. That type of electrical panel repair is disruptive, but waiting doesn’t make it cheaper or safer.

Smart panels and load centers with plug-on neutral features are changing how we approach upgrades. They simplify AFCI and GFCI deployment and tidy up neutrals, which cuts down on loose connections. If your panel is older than 25 to 30 years, spare parts are limited and safety expectations have shifted. Replacement typically makes sense when you plan to add a vehicle charger, solar interconnection, or additional HVAC equipment. Planning ahead lets you size the service to 200 amps or more, which in practice avoids nuisance trips and excessive voltage drop on heavy-use days.

Common defects I find in Houston homes

Every market has its greatest hits. Around Houston, a short list appears often enough that I check for it first.

Backstabbed receptacles in kitchens and laundry rooms, often original to homes from the 90s and early 2000s. High current draw and vibration work those connections loose. Moving to screw terminals during electrical wiring repair improves reliability markedly.

Shared neutrals without proper two-pole breakers or handle ties. When circuits share a neutral, the breakers must trip together. Without that, you can disconnect one hot while the shared neutral stays energized through the other circuit. I’ve run into this frequently in remodels where walls were opened and circuits re-routed quickly.

Nonmetallic cable in hot attics that exceeds temperature ratings. A mid-summer attic can hit 140 to 160 degrees. Derating matters. When you bundle too many cables across long runs, even a correctly sized breaker doesn’t protect against premature insulation damage. Spacing and routing corrections reduce risk.

Improperly installed EV chargers and generators. The appetite for backup power is strong after storms, but DIY interlocks and extension cords create lethal backfeed risks. A listed transfer switch or interlock kit, correctly installed, prevents sending power back to the utility lines and protects your home’s loads.

Water-damaged equipment. After a plumbing leak or storm, do not assume electrical gear is fine because it dries out. Breakers and GFCI devices that got wet are unreliable. Outlets affected by water, even briefly, should be replaced. Panels that took on water need a careful evaluation at minimum, and often a full change-out.

Safety checks before problems surface

Early inspections find issues while they are cheap to fix. The best cadence I’ve seen for residential electrical repair in our area looks like this: a baseline inspection when you move in, a quick check before summer, and a heavier inspection before major renovations or equipment additions. Rental properties benefit from an annual check, especially in student-heavy or high-turnover areas where devices take more abuse.

Some signals sound small but are worth a call. If a breaker trips more than once in a short time, document the timing, the loads in use, and any weather events. If lights dim when a microwave runs, note which lights and for how long. Intermittent problems can be the hardest to trace. A simple log becomes the difference between guesswork and targeted testing.

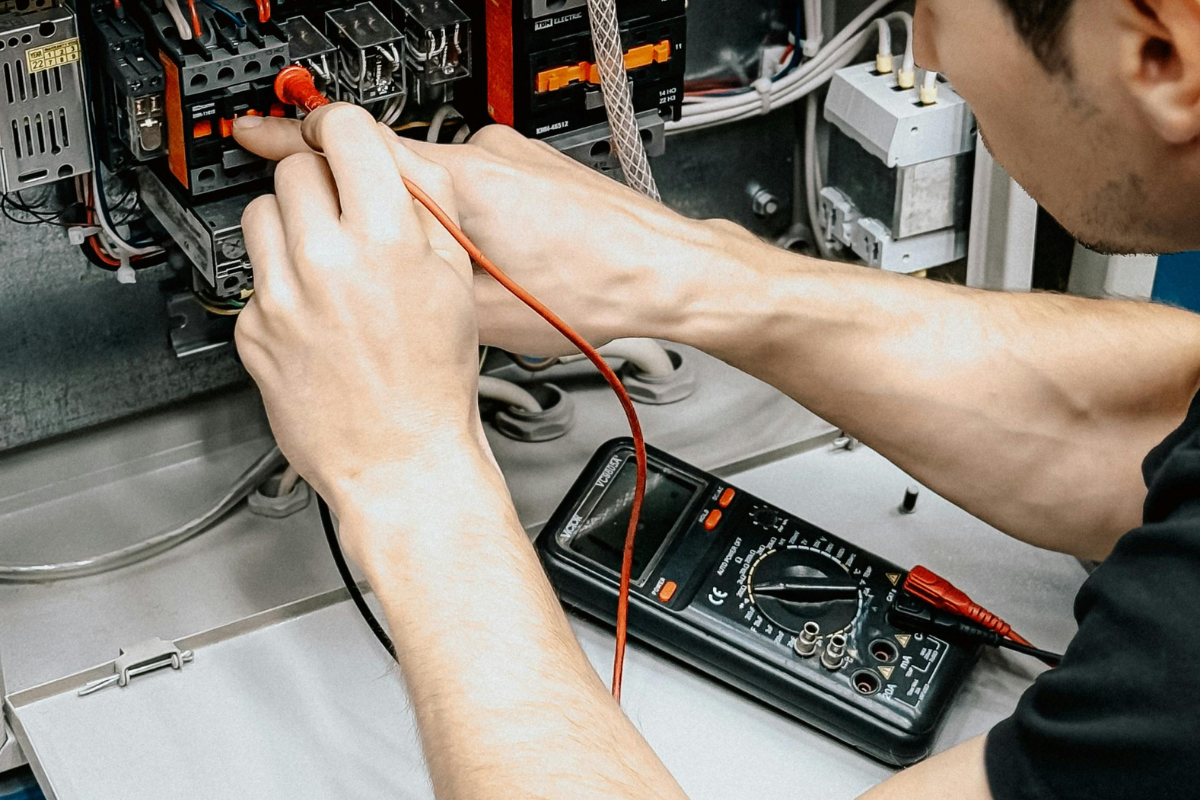

How licensed electricians test and verify

Good testing looks methodical, not flashy. We measure voltage at the service and under load, checking for drop across main lugs and feeders. We test outlets for polarity, grounding, and GFCI/AFCI function. Infrared scanning locates hot spots at terminations. A clamp meter helps check load distribution across legs and flags imbalances that point to poor neutrals or overloaded circuits.

Insulation resistance testing has a place in older homes and on long exterior runs. It can reveal moisture-wicked conductors that ordinary continuity checks miss. For aluminum branch circuits, I inspect terminations for approved connectors and antioxidant compounds. Where problems cluster, I may recommend a COPALUM crimp or AlumiConn approach approved for aluminum-to-copper transitions. That advice depends on the home’s layout, the number of problem devices, and the owner’s budget and timeline.

What homeowners can safely monitor

Most electrical repair services hinge on conditions that a homeowner can spot early without touching live parts. You do not need a multimeter to notice a switch plate that grows warm without a dimmer, or a panel that smells like hot plastic. A humming breaker or random resetting GFCI should prompt service. Newer homes often hide junctions in accessible attics and garages. A quick seasonal look for exposed conductors, missing box covers, or chewed insulation from pests can save time and money later.

I advise clients to photograph their panel labeling, keep receipts for appliances and major electrical work, and track past repairs. When a breaker trips, write down the date, time, loads in use, and weather conditions. That context narrows the diagnosis sharply.

What to expect during a professional home electrical repair visit

A good contractor starts with questions. What changed recently, what work has been done, which circuits misbehave, and when. We inspect the service and panel before touching outlets downline. If the issue is localized, we isolate the affected circuit and inspect boxes in order, starting with the last known good point. On fishing wire through finished walls, we prefer existing chases and cavities to minimize patching. Where we must cut access, we do it small and in sensible places so drywall repair is straightforward.

For electrical panel repair, expect power to be off for at least part of the visit. If we replace the panel or main breaker, plan for several hours without power, sometimes a full day for service upgrades that require utility coordination. Permits are not red tape to be avoided, they protect you at resale and ensure the work is inspected. Most Houston-area jurisdictions move quickly on residential permits for like-for-like repairs.

Cost ranges and realistic timelines

Prices vary by home size, equipment, and access, but patterns hold. A focused troubleshooting visit that resolves a simple loose connection typically runs a few hundred dollars. Replacing a handful of worn receptacles and switches, correcting a double-tap, and cleaning up a panel might sit in the mid hundreds to low four figures, especially if we add AFCI or GFCI devices. Full panel replacement, depending on amperage and brand, often lands in the low to mid four figures, with service upgrades higher. Whole-home surge protection devices range widely, but a quality unit installed at the main panel usually fits comfortably into a repair visit.

Timelines compress in peak summer and after storms. The shops you want to hire will prioritize safety issues first. If a contractor offers to swap your panel same day without a permit or utility coordination where needed, ask hard questions. Speed matters, but so does doing it right.

When repair is better than replacement, and when it isn’t

Not every problem requires new equipment. Tightening terminations, rerouting a few circuits, replacing a failed breaker, or reterminating a scorched receptacle are clean, durable fixes. If the panel is modern, dry, and listed for the installed breakers, electrical panel repair is absolutely worth it.

Replacement wins when the equipment is obsolete, damaged by water or heat, undersized for present and future loads, or when recurring nuisance trips trace back to the panel itself. I also recommend replacement when parts availability is thin or when we plan to add an EV charger, larger HVAC, or potential solar tie-in. Spending money twice rarely pleases anyone. Planning one step ahead prevents that.

Surge protection and modern electronics

Houston’s storm activity and grid events make a strong case for layered surge protection. A quality Type 1 or Type 2 device at the panel shunts big spikes. Plug-in strips with real surge ratings protect individual electronics from smaller transients and offer extra filtration. Protection is a system, not a single device. If your grounding and bonding are weak, surge protection underperforms. During inspections, we verify the grounding electrode system, bond the water piping where applicable, and ensure the panel’s neutral to ground relationship is correct for the service configuration.

Homes with generators and transfer switches add another layer. The surge device needs to play nicely with the generator’s neutral bonding scheme. The details matter, and this is where professional electrical repair services earn their keep.

The case for GFCI and AFCI beyond minimum code

Codes evolve because data accumulates. GFCI has reduced shock incidents dramatically, and AFCI cuts down on fires from arcing faults that standard breakers do not catch. Many Houston homes still lack AFCI on bedroom circuits if they predate adoption of those requirements. If you have a nursery, a home office with lots of electronics, or older aluminum branch circuits, extending AFCI can be a smart upgrade. Nuisance trips happen when devices are faulty or wiring is marginal, which is precisely the point. If trips are frequent, we find and fix the cause. The end state is a safer, more stable system.

Working with an electrician you can trust

Credentials and process beat slogans. Look for a master license, insurance, and permits pulled when required. Ask how the technician documents findings. Photos of thermal anomalies, torque verification notes, and a clean panel after the visit tell you as much about a company as a review score. I value clients who ask for options at different price points, because there is always more than one way to solve a problem. A good contractor explains trade-offs plainly: repair now and recheck in six months, or replace now and avoid future visits.

Seasonal playbook for Houston homeowners

Here is a concise plan that aligns with our climate and typical loads.

- Spring: schedule an inspection focused on the panel, HVAC circuits, grounding, and exterior receptacles. Address any heat-related concerns before summer.

- Summer: monitor for dimming lights, warm breakers, and frequent GFCI trips outdoors. Keep panel area clear for airflow. Call early for any burning odor.

- Fall: test smoke and CO alarms, review generator and transfer switch operation, confirm surge protection status, and check attic wiring after the hottest months.

- Winter: if using space heaters, verify dedicated circuits or limit use to one heater per circuit. Inspect holiday lighting connections and avoid daisy-chaining strips.

Where DIY ends

Homeowners can replace faceplates, swap a broken receptacle or switch on a de-energized circuit, and reset tripped GFCIs safely if they understand the basics. Anything involving the panel, aluminum terminations, shared neutrals, multiwire circuits, or evidence of heat or water damage belongs to a licensed electrician. The risks are not theatrical. A single miswired neutral can energize a metal fixture, and a panel that looks clean might hide a brittle bus that fails when a breaker is moved.

A note on older and historic homes

I have a soft spot for older Houston properties. Knob-and-tube appears less frequently these days, but I still find cloth-insulated conductors and ungrounded circuits that owners want to preserve while upgrading functionality. The right approach is selective rewiring during other renovations, adding grounded circuits to high-use rooms, and leaving low-load lighting circuits undisturbed if they test sound and meet safety needs. When grounding isn’t feasible at a receptacle, a GFCI-protected, labeled “No Equipment Ground” outlet provides protection and honesty for anyone plugging in sensitive electronics.

The payoff of doing it right

Electrical systems reward attention. After a well executed inspection and repair, lights stop dipping, outlets feel tight and cool, the panel looks organized and labeled, and trips are rare and meaningful. Insurance carriers notice documented upgrades. Appraisers notice legitimate permits. Most importantly, your home feels calmer. You don’t think about the hum behind the drywall, which is the best outcome there is.

If your last electrical check happened years ago, or if “never” is closer to the truth, start with a targeted inspection. Tell the technician how you live in the home: EV charging, a backyard workshop, multiple gaming PCs, large fish tanks, or a pottery kiln in the garage. Reality drives good design. Houston’s environment then sets the constraints. A professional who respects both will guide you to the right mix of maintenance, electrical repair, and upgrades.

Final advice grounded in Houston practice

Choose timing wisely. Book inspections before peak heat. Keep an eye on any circuit that runs long in conduit outside or through the attic. Prioritize the main service, grounding, and the panel before spending on decorative fixtures or gadgets. If you add a major load, budget for the upstream work to support it. And if something smells hot or looks discolored, turn it off and call. Most failures telegraph their arrival. A good inspection is how you learn to listen.

All American Electric LLC

Address: 9230 Keough Rd #100, Houston, TX 77040

Phone: (713) 999-3531